Induction Cooking - History of Induction Cooker

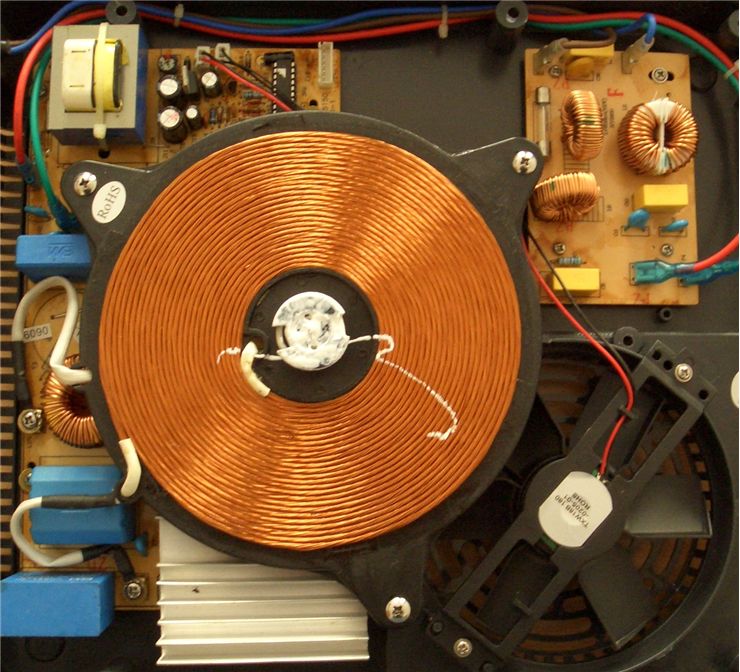

Induction cooking is a method of cooking where induction heating is used to directly heat a cooking vessel. With induction heating, a ferromagnetic material is heated by electromagnetic induction when a current that is inducted in the material, from an outer electric source, produces heat through resistive heating. That is why a cooking vessel must be made of a ferromagnetic metal, or, if not, to be placed on an interface disk which is made of the same type of metal.

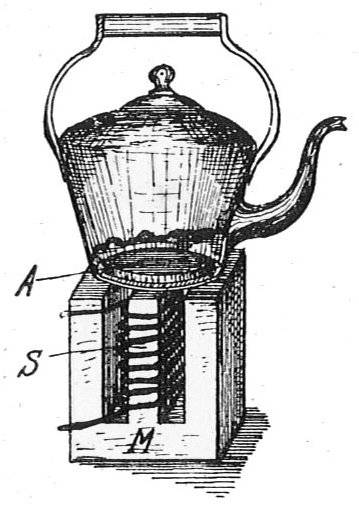

Induction cooker has a coil of copper wire placed underneath the cooking pot and alternating electric current flows through it. Even the first patents for induction cookers that appeared at the beginning of the 20th century had the same principle. From that moment until the 1970s, induction cooking appeared only as a demonstration of technology and was used primarily for annealing metal in industrial applications but it was not in general use. At the Chicago "Century of Progress" World's Fair in 1933, induction cooking technology was introduced to the world. Frigidaire, a division of General Motors, demonstrated induction cookers on a touring GM showcase in North America in the mid-1950s.

Research & Development Center of Westinghouse Electric Corporation developed the first modern induction stoves in America in the early 1970s. These were for the first time put on public display at the 1971 National Association of Home Builders convention in Houston, Texas. They were of stand-alone single-burner type and were called the Cool Top Induction Range. From this type, the first series was developed called Cool Top 2 (CT2) Induction range. The development work was done at the same Research & Development Center and a team was led by Bill Moreland and Terry Malarkey. Market price of an individual induction stove was $1,500. It included a of high quality cookware made of so called Quadraply, which is a type of laminate made of layers of stainless steel, carbon steel and aluminum. Cool Top 2 (CT2) Induction range had four burners of about 1,600 watts each, and was in production from 1973 to 1975. Sears Kenmore, an exclusive brand of household appliances established by Sears, sold their free-standing oven/stove with four induction-cooking surfaces in the mid-1980s. These early induction stoves had low power, reliability and noise problems. American manufacturers made their last induction stoves for home use in 1999. Europe and Asia continued to develop their variants and US manufacturers like Cooktek and Luxine continued to develop commercial units used in the food service industry. Panasonic developed an all-metal induction cooker in 2009. It can use non-ferrous metal cookware but it has reduced coupling efficiency and with that can produce less heat.

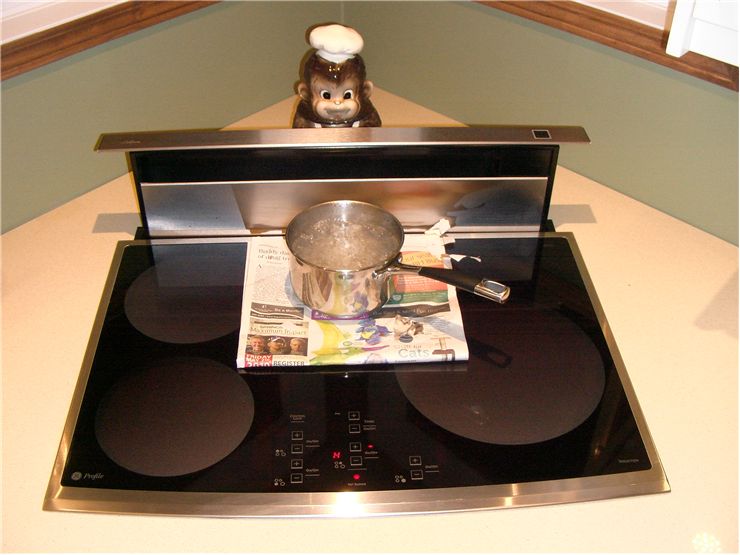

Induction cookers provide rapid heating, have improved thermal efficiency and can be controlled like gas stoves. Induction plate is cold when in use and has no open flame which makes it safer. Induction cookers also have control systems that shut down the element if a pot is not present or not large enough.

Limitation of induction cooker is that cookware must be compatible for this kind of use. Glass and ceramics cannot be used as well as solid copper or solid aluminum (except on all-metal induction cookers). Glass ceramic top a stove can be damaged by impact. Aluminum foil can melt onto the top and cause permanent damage or cracking of the top.